Load cells are essential instruments for measuring weight or force. They play a vital role in a wide range of industries, such as manufacturing, healthcare, automotive, and food processing. These precision devices convert mechanical force into electrical signals, allowing for the accurate measurement of weight or strain.

As technology continues to evolve, an in-depth understanding of the various types of load cells, such as strain gauge, hydraulic, and pneumatic, becomes increasingly important. Each type operates on distinct principles and is suited for specific applications, ranging from industrial scales to structural health monitoring.

Understanding Load Cells

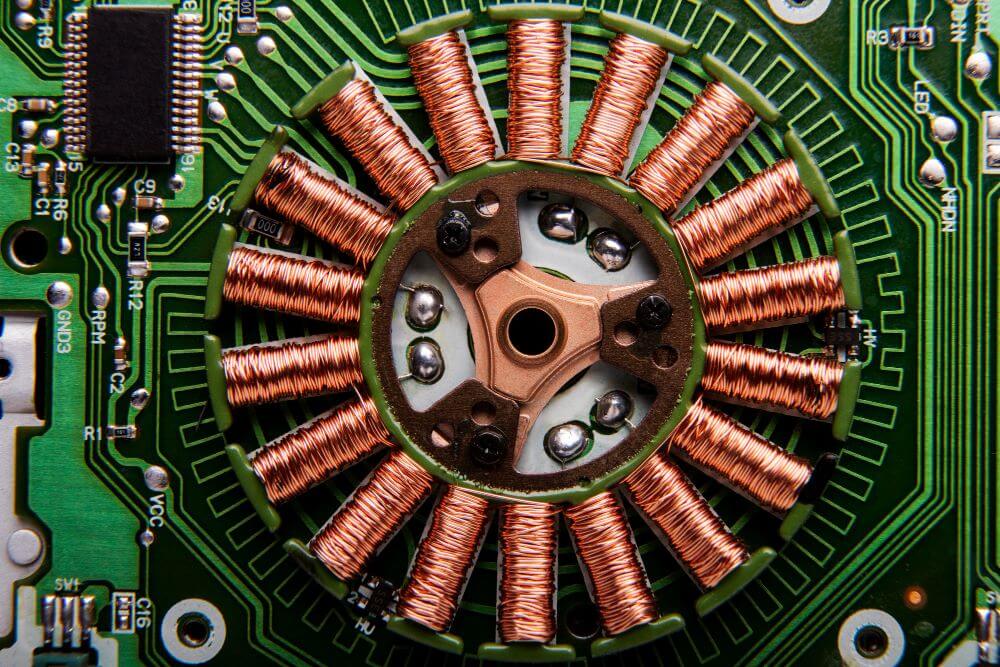

A load cell is a transducer used to convert the force or weight into an electrical signal. This conversion enables precise measurements, which is crucial in many environments. Typically, these devices contain strain gauges that change under load, providing a mechanism for altering electrical resistance and more about how a load cell functions. That essentially changes into an outputting unit, giving you a complete analysis of force or weight usage.

Types of Load Cells

Different types of load cells are available, and each type is used for particular tasks. We very often see hydraulic, pneumatic, and strain gauge load devices. In hydraulic models the force measurement is done upon hydraulic fluid pressure, making them a strong choice in demanding conditions. Pneumatic – It uses air pressure, and this is an exact and safe type of load cell that is suitable for explosive environments. One of the most popular load cells used, strain gauge load cells, rely on changes in electrical resistance to measure force and, therefore, have a high level of accuracy and versatility.

Applications in Manufacturing

Load Cells are crucial in controlling quality and safety in manufacturing industries. These devices ensure that components remain within weight specifications in assembly lines, avoiding defects. They also monitor machine load and prevent wear and tear by operating within sensible limits. As a result, load cells have become an indispensable component of many manufacturing processes, improving efficiency and reducing downtime.

Role in Transportation

Load Cells for Transportation It would be insightful to mention here that transportation sectors receive enormous leverage from load cells and vehicle weighing systems in particular. Precise weight measurement helps in adhering to regulations, saves from penalties, and supports road safety. Load cells are also used to ensure the load is evenly distributed through a container cargo so that it can be fuel efficient and not carry an excessive amount of weight. This technological integration makes the operation more efficient and cost-effective.

Impact on Healthcare

Load cells are used in healthcare, where they are embedded in the industry for patient monitoring and medical equipment. When integrated into hospital beds, load cells allow weight to be recorded in real-time, assisting in patient care and facilitating treatment adjustments. Furthermore, load cells play an essential role in the accurate dispensing of medications, reducing errors and ensuring patient safety. These contribute to enhancing healthcare outcomes and increasing efficiency.

Use in Agriculture

For example, load cells are used in agriculture to weigh livestock and detect feed levels. Accurately monitoring livestock weight helps track their growth and health, which affects decisions regarding feed and breeding. Furthermore, load cells guarantee the exact delivery of feed, which improves animal nutrition and minimizes wastage. Such innovations facilitate sustainable agricultural practices and better productivity.

Contribution to Retail

Load cells can also be found in scales used in retail industries to weigh products. Such accuracy keeps customers without the worry of getting the wrong quantity. Load cells also play a role in inventory management, delivering live data to assist with stock control and replenishment. Load cells can be used in retail to improve efficiency and customer experience.

Future Trends

Advancements in Load Cell Technology Precision and Integration Itself Some of the instant trends are communication through wireless and Smart systems to access and analyse data in real time. These advancements will allow for a seamless connection to the Internet of Things, allowing for more flexible automation and decision-making. Advanced innovations in load cell technology will boost efficiency and accuracy across diverse industries.

Conclusion

Load Cells are essential tools in many sectors that facilitate weight and force measurements. Their applications, spanning manufacturing to healthcare, allow for enhanced precision and efficiency. With the advancement of technology, the demand for load cells within the industry will only continue to increase. Knowledge of their functions and applications ensures that these tests are used appropriately and that the outcomes are optimised in a variety of settings.